Off the Shelf

- New and prototype components

- Composite Medivac Stretcher

- Control column grips

- Control knobs

Our team of over 60 professionals ensures we remain one of NZ’s leading aerospace manufacturers. A combination of advanced manufacturing technologies with traditional techniques ensures that every product meets the highest standards of quality and performance, tailored to your specific needs.

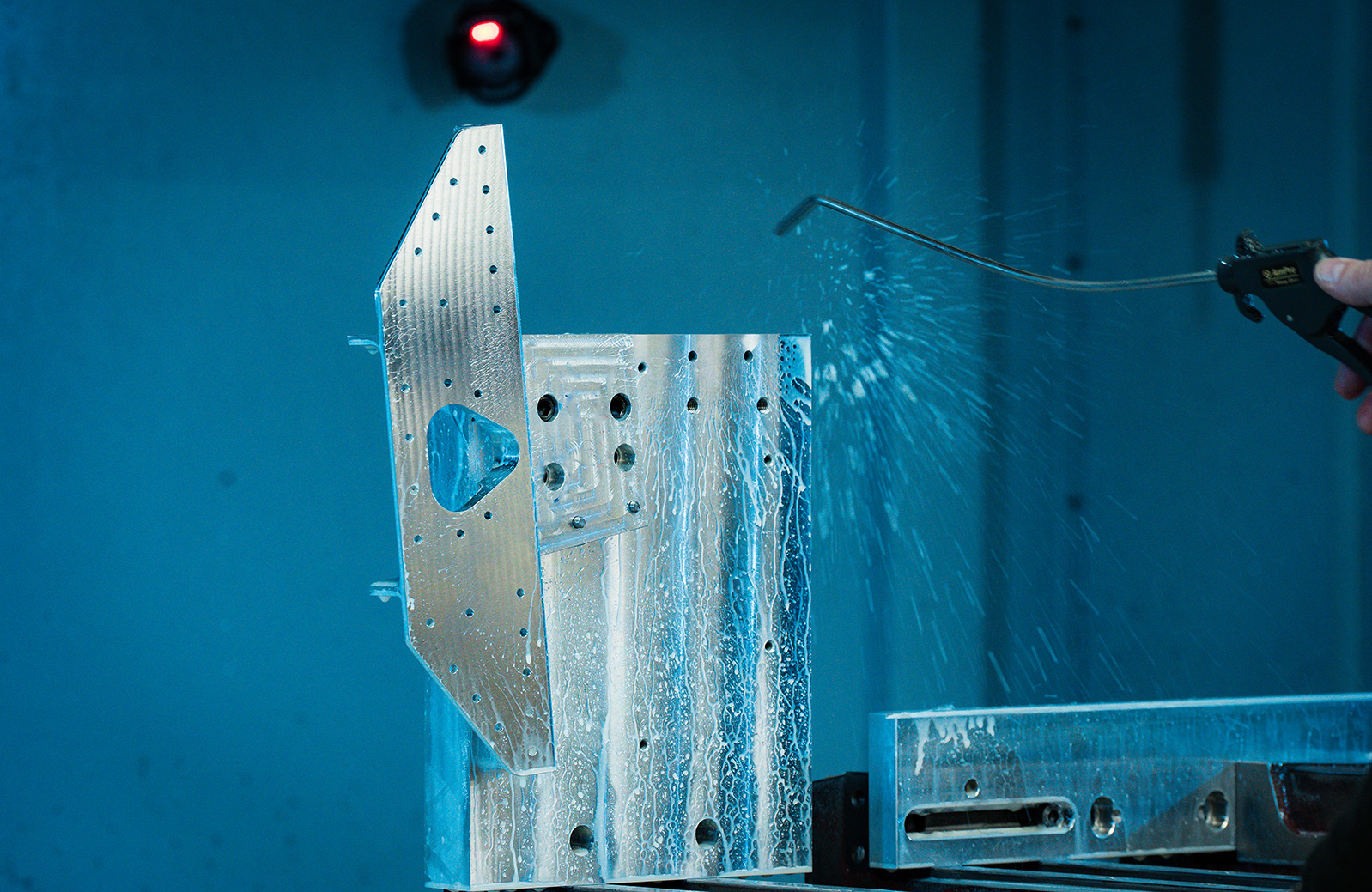

From machined milling and precision machining to post-processing and assembly, we offer turnkey solutions in specialised materials, meeting the most complex and demanding requirements. With all services performed onsite at our state-of-the-art 12-acre facility in Hamilton, New Zealand, you can count on us for fast turnaround times that align with your operational demands.

Our precision engineering team excels in delivering high-quality products with rapid development and precise machining, complemented by comprehensive post-processing services.

Crafting custom parts with precise tolerances using advanced rotary cutters to create complex 3D shapes on various materials. Precision machining ensures high-quality production

Offering bending, shearing, staking, laser cutting, stamping, and more to create highly complex parts efficiently without costly and time-consuming tooling.

Specialised in compression molding, transfer molding, vacuum molding, and laminating for a wide range of materials.

Welding critical materials and components, ensuring safety and reliability in every project.

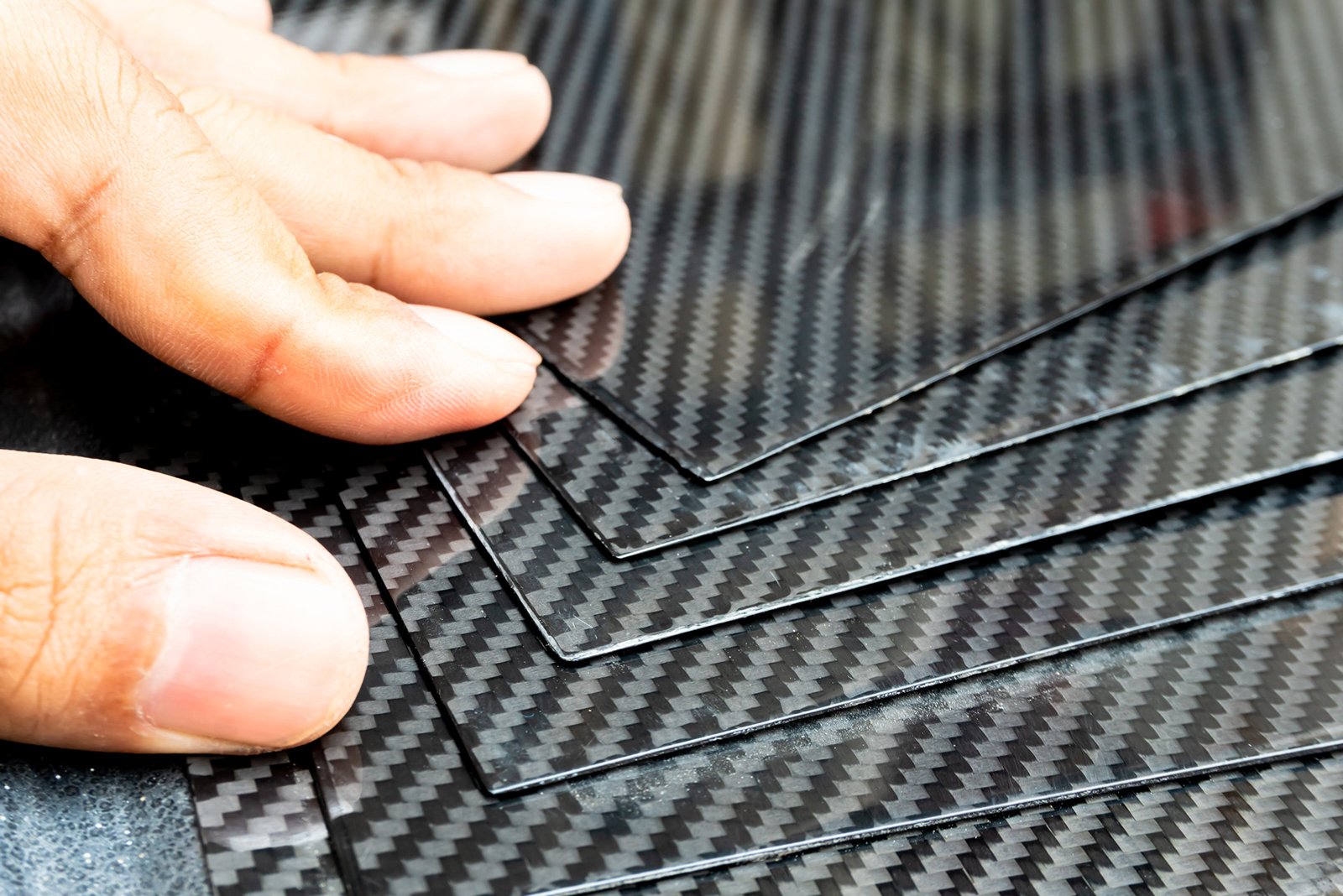

Leading in innovation with transparencies, fiberglass, carbon composites, and more.

Contact us today to discuss your precision engineering needs and how we can bring your vision to life.

With a proud heritage supporting the Royal New Zealand Air Force, NZAero Precision Engineering have expanded globally, partnering with industry leaders like Boeing, the RAAF and the US Navy. We offer solutions for a multitude of aircraft, including agricultural and military as well as aerospace projects.

Our commitment to research and development drives us to continuously refine our cutting-edge capabilities.

Our commitment to research and development drives us to continuously refine our cutting-edge capabilities. You benefit from a wide range of materials, including fiberglass and carbon composites, crafted through advanced techniques like hand lay-ups, vacuum bagging, resin infusion, and cold casting.

Our design team works with you to create custom patterns and molds that meet CAA NZ-approved aeronautical design standards. We ensure that every product is designed to your specifications, delivering quality and precision.

A specialised division focuses on aircraft windows, windscreens, and canopies, providing high-quality, reliable components that meet strict aviation standards.

Explore Our Composite Capabilities and see how we can support your project from concept to completion.

Ready to advance your aerospace manufacturing?

Contact us today to discuss how we can meet your precision engineering needs.